T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon Steel

DIN2445

st37.4/52.4

| Availability: | |

|---|---|

| Quantity: | |

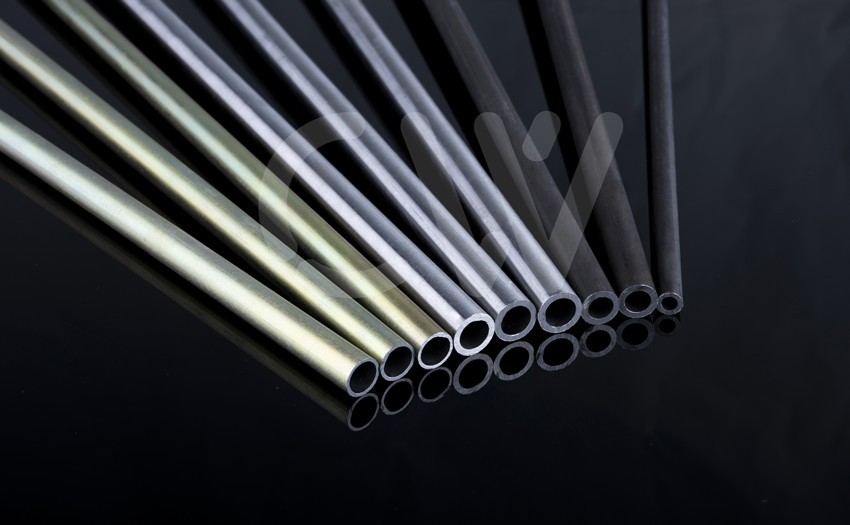

DIN 2445 ST37.4 OD 5mm hydraulic galvanized precision steel tube

Certificates: according to EN 10204 3.1

Inspection Items: Tensile stength, Yield stength, Elongation, Flattenging, Flaring

Chemical analysis

Eddy Current Test 100%, Size and surface checking 100%

Other test item can be arranged as per request

SIZE TOLERANCE | |||||

NAME |

Scope (mm) |

GB Series (mm) |

DIN series (mm) | Enterprise internal control standards (mm) |

Special high-precision (mm) |

Out diameter

| 2-30 | ±0.10 | ±0.08 | ±0.05 | ±0.03 |

31-40 | ±0.15 | ±0.15 | ±0.05 | ±0.03 | |

41-50 | ±0.20 | ±0.20 | ±0.08 | ±0.03 | |

51-60 | ±0.25 | ±0.25 | ±0.08 | ±0.03 | |

Wall thickness | 0.3-10 | ±10%; MIN±0.15 | ±10% | ±10%; MIN±0.05 | ±10%; MIN±0.03 |

Delivery Conditions

| Designaion | Symbol | Description |

| Cold drawn/hard | +C | No heat treatment after the final cold drawing process. |

| Cold drawn/soft | +LC | After the final heat treatment there is a suitable drawing pass. |

| Cold drawn and stress relieved | +SR | After the final cold drawing process there is a stress relief heat treatment in a controlled atmosphere. |

| Annealed | +A | After the final cold drawing process the tubes are annealed in a controlled atmosphere. |

| Normalized | +N | After the final cold drawing operation the tubes are normalized in a controlled atmosphere. |

Product Name: DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube

Product Overview

The DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube is a premium-grade engineered solution specifically developed for demanding hydraulic applications. Manufactured in strict compliance with DIN 2445 standards and enhanced with a protective zinc coating, this tube delivers exceptional corrosion resistance, precise dimensional accuracy, and reliable performance in high-pressure hydraulic systems across various industrial sectors.

Material Specification

Steel Grade: ST37.4 Carbon Steel

Composition: Optimized blend of carbon, manganese, silicon, phosphorus, and sulfur elements, ensuring superior mechanical strength, excellent ductility, and enhanced weldability for fabrication flexibility.

Key Features

Precision Engineering

Manufactured to exacting dimensional tolerances with a smooth internal surface, enabling optimal fluid dynamics, reduced pressure loss, and seamless compatibility with hydraulic components.

Advanced Galvanized Protection

The electro-galvanized zinc coating provides robust defense against corrosion, rust, and environmental degradation, significantly extending service life in moist or aggressive operating conditions.

High-Pressure Reliability

Engineered with reinforced structural integrity to withstand extreme hydraulic pressures, ensuring leak-free operation and long-term system safety.

Broad Application Versatility

Ideal for hydraulic cylinders, power transmission lines, control systems, and other critical components across automotive, construction, agricultural, and industrial machinery sectors.

Technical Parameters

Outer Diameter: 4mm–80mm (customizable)

Wall Thickness: 0.5mm–10mm (customizable)

Length: Custom-cut to requirements

Dimensional Tolerance: Compliant with DIN 2445 or customer specifications

Surface Treatment: Galvanized finish

Product Advantages

Standards Compliance: Fully conforms to DIN 2445 quality and precision benchmarks

Material Excellence: ST37.4 steel ensures optimal strength-formability balance for hydraulic use

Corrosion Defense: Galvanized layer offers superior protection in challenging environments

Precision Fit: Tight tolerances facilitate easy integration and reliable sealing

Dynamic Durability: Designed to maintain performance under continuous operation and mechanical stress

Cross-Industry Suitability: Adaptable to diverse hydraulic applications requiring longevity and precision

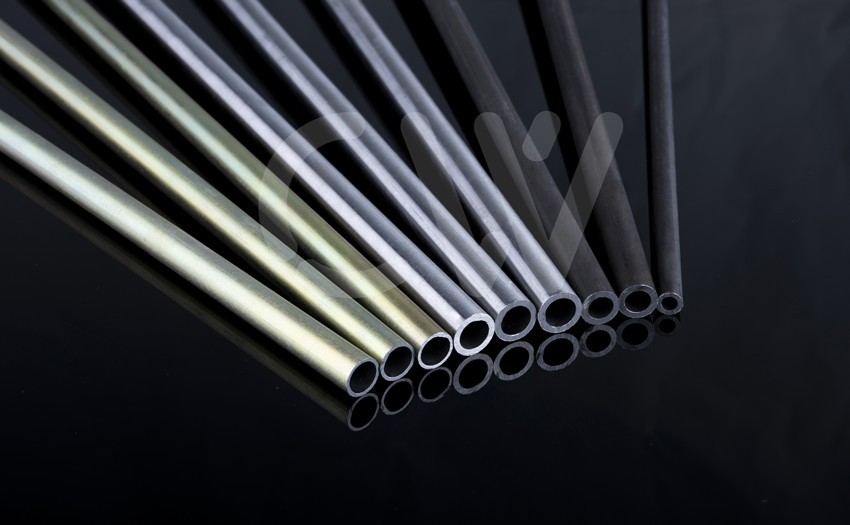

DIN 2445 ST37.4 OD 5mm hydraulic galvanized precision steel tube

Certificates: according to EN 10204 3.1

Inspection Items: Tensile stength, Yield stength, Elongation, Flattenging, Flaring

Chemical analysis

Eddy Current Test 100%, Size and surface checking 100%

Other test item can be arranged as per request

SIZE TOLERANCE | |||||

NAME |

Scope (mm) |

GB Series (mm) |

DIN series (mm) | Enterprise internal control standards (mm) |

Special high-precision (mm) |

Out diameter

| 2-30 | ±0.10 | ±0.08 | ±0.05 | ±0.03 |

31-40 | ±0.15 | ±0.15 | ±0.05 | ±0.03 | |

41-50 | ±0.20 | ±0.20 | ±0.08 | ±0.03 | |

51-60 | ±0.25 | ±0.25 | ±0.08 | ±0.03 | |

Wall thickness | 0.3-10 | ±10%; MIN±0.15 | ±10% | ±10%; MIN±0.05 | ±10%; MIN±0.03 |

Delivery Conditions

| Designaion | Symbol | Description |

| Cold drawn/hard | +C | No heat treatment after the final cold drawing process. |

| Cold drawn/soft | +LC | After the final heat treatment there is a suitable drawing pass. |

| Cold drawn and stress relieved | +SR | After the final cold drawing process there is a stress relief heat treatment in a controlled atmosphere. |

| Annealed | +A | After the final cold drawing process the tubes are annealed in a controlled atmosphere. |

| Normalized | +N | After the final cold drawing operation the tubes are normalized in a controlled atmosphere. |

Product Name: DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube

Product Overview

The DIN 2445 ST37.4 Hydraulic Galvanized Precision Steel Tube is a premium-grade engineered solution specifically developed for demanding hydraulic applications. Manufactured in strict compliance with DIN 2445 standards and enhanced with a protective zinc coating, this tube delivers exceptional corrosion resistance, precise dimensional accuracy, and reliable performance in high-pressure hydraulic systems across various industrial sectors.

Material Specification

Steel Grade: ST37.4 Carbon Steel

Composition: Optimized blend of carbon, manganese, silicon, phosphorus, and sulfur elements, ensuring superior mechanical strength, excellent ductility, and enhanced weldability for fabrication flexibility.

Key Features

Precision Engineering

Manufactured to exacting dimensional tolerances with a smooth internal surface, enabling optimal fluid dynamics, reduced pressure loss, and seamless compatibility with hydraulic components.

Advanced Galvanized Protection

The electro-galvanized zinc coating provides robust defense against corrosion, rust, and environmental degradation, significantly extending service life in moist or aggressive operating conditions.

High-Pressure Reliability

Engineered with reinforced structural integrity to withstand extreme hydraulic pressures, ensuring leak-free operation and long-term system safety.

Broad Application Versatility

Ideal for hydraulic cylinders, power transmission lines, control systems, and other critical components across automotive, construction, agricultural, and industrial machinery sectors.

Technical Parameters

Outer Diameter: 4mm–80mm (customizable)

Wall Thickness: 0.5mm–10mm (customizable)

Length: Custom-cut to requirements

Dimensional Tolerance: Compliant with DIN 2445 or customer specifications

Surface Treatment: Galvanized finish

Product Advantages

Standards Compliance: Fully conforms to DIN 2445 quality and precision benchmarks

Material Excellence: ST37.4 steel ensures optimal strength-formability balance for hydraulic use

Corrosion Defense: Galvanized layer offers superior protection in challenging environments

Precision Fit: Tight tolerances facilitate easy integration and reliable sealing

Dynamic Durability: Designed to maintain performance under continuous operation and mechanical stress

Cross-Industry Suitability: Adaptable to diverse hydraulic applications requiring longevity and precision