T: +86-512-58335585

E: sale@chewit.cn

E: sale@chewit.cn

Shuangshan Road, Jingang Town, Zhangjiagang City, Jiangsu Province, China

Carbon Steel

as per request

as per request

| Availability: | |

|---|---|

| Quantity: | |

Detailed Image

SIZES AND TOLERANCE

| Mechanical properties at room temperature | |||||||||

| Delivery condition | BK | BKW | GBK | NBK | |||||

| steel Grade | Rm Mpa (Min) | A %(Min) | Rm Mpa(Min) | A %(Min) | Rm Mpa(Min) | A %(Min) | Rm Mpa(Min) | ReH Mpa(Min) | A %(Min) |

| St30Al or E215 | 430 | 8 | 380 | 12 | 280 | 30 | 290 to 430 | 215 | 30 |

| St35 or E235 | 480 | 6 | 420 | 10 | 315 | 25 | 340 to 480 | 235 | 25 |

| St45 or E255 | 580 | 5 | 520 | 8 | 390 | 21 | 440 to 570 | 255 | 21 |

| St52 or E355 | 640 | 4 | 580 | 7 | 450 | 22 | 490 to 630 | ||

Description

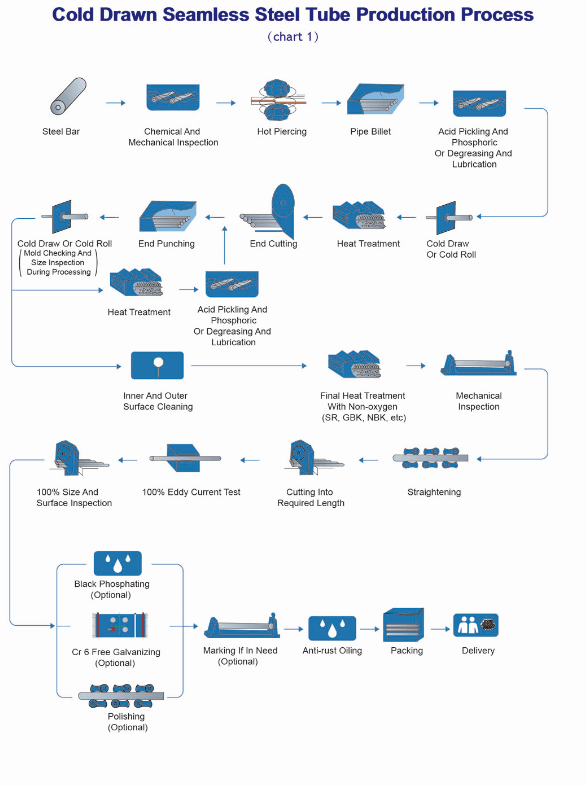

This product refers to high-quality carbon precision seamless steel tubes manufactured in accordance with standards DIN 2391 and EN 10305. Grades include St35, St37.4, and St52. The production process involves cold drawing and bright heat treatment under a controlled atmosphere to achieve an oxidation-free surface (NBK condition). Tubes also undergo non-destructive testing, thorough cleaning, phosphating, and anti-rust oil immersion, making them suitable for applications requiring high precision, excellent surface brightness, internal cleanliness, and reliable mechanical properties.

Key Features & Advantages:

Phosphated Surface Treatment: The tubes are treated with imported chemical solutions to form a uniform black phosphate coating. This micro-porous film effectively absorbs anti-rust oil, significantly enhancing corrosion resistance. Both ends of the tube are capped to prevent dust ingress.

Superior Dimensional and Surface Quality: High dimensional accuracy and excellent surface brightness are guaranteed. After heat treatment, both inner and outer walls remain free from oxidation, with a clean and smooth internal surface.

Outstanding Mechanical Performance: The tubes withstand high pressure and demonstrate excellent structural integrity—resisting deformation during cold bending, and cracking under flaring or flattening tests. They are suitable for complex shaping and machining operations.

Uniform Appearance and Rust Resistance: The NBK-treated tubes exhibit a consistent bright-black finish across the surface, combining aesthetic uniformity with prolonged rust prevention.

Typical Applications:

These precision tubes are widely used in machine tools, construction machinery, shipbuilding hydraulic systems, automotive components, and other applications demanding high precision, bright surfaces, cleanliness, and superior mechanical properties.

APPLICATIONS

1. Automotive fields

A. Fuel injection lines/nozzles

B. CNG (Compressed Nature Gas) tube-- Burst pressure: 1307Bar, Working Pressure: around 350bar

C. Drive transmission: Steering column elements

D. Gear shafts, hand brake, front axles, airbag inflators, stabilizers, seat fasteners, front-wheel drive shafts

2. Hydraulic Fields

A. Hydraulic circuits (HPL), pneumatic lines, and hydraulic suspension

B. Hydraulic cylinders (HPZ)

Packaging workshop

Packaging is the ultimatee of product quality .we establish strict packaging quality management system to improve packaging quality of products continuously and pack products strictly in accordance with packaging standars and customer requirements.

Detailed Image

SIZES AND TOLERANCE

| Mechanical properties at room temperature | |||||||||

| Delivery condition | BK | BKW | GBK | NBK | |||||

| steel Grade | Rm Mpa (Min) | A %(Min) | Rm Mpa(Min) | A %(Min) | Rm Mpa(Min) | A %(Min) | Rm Mpa(Min) | ReH Mpa(Min) | A %(Min) |

| St30Al or E215 | 430 | 8 | 380 | 12 | 280 | 30 | 290 to 430 | 215 | 30 |

| St35 or E235 | 480 | 6 | 420 | 10 | 315 | 25 | 340 to 480 | 235 | 25 |

| St45 or E255 | 580 | 5 | 520 | 8 | 390 | 21 | 440 to 570 | 255 | 21 |

| St52 or E355 | 640 | 4 | 580 | 7 | 450 | 22 | 490 to 630 | ||

Description

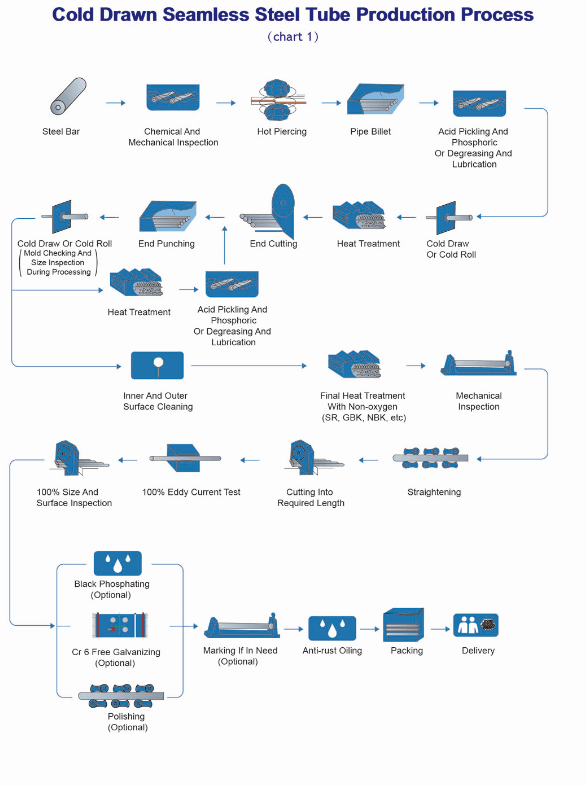

This product refers to high-quality carbon precision seamless steel tubes manufactured in accordance with standards DIN 2391 and EN 10305. Grades include St35, St37.4, and St52. The production process involves cold drawing and bright heat treatment under a controlled atmosphere to achieve an oxidation-free surface (NBK condition). Tubes also undergo non-destructive testing, thorough cleaning, phosphating, and anti-rust oil immersion, making them suitable for applications requiring high precision, excellent surface brightness, internal cleanliness, and reliable mechanical properties.

Key Features & Advantages:

Phosphated Surface Treatment: The tubes are treated with imported chemical solutions to form a uniform black phosphate coating. This micro-porous film effectively absorbs anti-rust oil, significantly enhancing corrosion resistance. Both ends of the tube are capped to prevent dust ingress.

Superior Dimensional and Surface Quality: High dimensional accuracy and excellent surface brightness are guaranteed. After heat treatment, both inner and outer walls remain free from oxidation, with a clean and smooth internal surface.

Outstanding Mechanical Performance: The tubes withstand high pressure and demonstrate excellent structural integrity—resisting deformation during cold bending, and cracking under flaring or flattening tests. They are suitable for complex shaping and machining operations.

Uniform Appearance and Rust Resistance: The NBK-treated tubes exhibit a consistent bright-black finish across the surface, combining aesthetic uniformity with prolonged rust prevention.

Typical Applications:

These precision tubes are widely used in machine tools, construction machinery, shipbuilding hydraulic systems, automotive components, and other applications demanding high precision, bright surfaces, cleanliness, and superior mechanical properties.

APPLICATIONS

1. Automotive fields

A. Fuel injection lines/nozzles

B. CNG (Compressed Nature Gas) tube-- Burst pressure: 1307Bar, Working Pressure: around 350bar

C. Drive transmission: Steering column elements

D. Gear shafts, hand brake, front axles, airbag inflators, stabilizers, seat fasteners, front-wheel drive shafts

2. Hydraulic Fields

A. Hydraulic circuits (HPL), pneumatic lines, and hydraulic suspension

B. Hydraulic cylinders (HPZ)

Packaging workshop

Packaging is the ultimatee of product quality .we establish strict packaging quality management system to improve packaging quality of products continuously and pack products strictly in accordance with packaging standars and customer requirements.